manufacturing space

employees in the company

Extrusion of PVC profiles

28 years of experience in the production of PVC extrusion has allowed us to develop the best recipes and technologies for creating high-quality products. The company has 23 PVC extrusion lines. High-quality equipment allows you to make a profile with good plasticization and impact resistance. Our own mixing workshop ensures the production of products with the best quality characteristics.

Production of PVC mixtures

A high-quality final product depends on many parameters, primarily on compliance with the correct recipe at the profile production stage. The presence of an automated mixing shop ensures the production of high-quality and stable raw materials, and also eliminates human errors. KONTINENT has 2 fully automated mixing centers, thanks to which we obtain unique colors, including anthracite gray, which is UV resistant, which is confirmed by laboratory tests.

Lamination and painting of PVC products

The plant has 5 lamination lines, allowing you to quickly decorate profiles and panels to individual customer orders in large volumes, as well as 2 flexo printing lines for panels. We use Israeli PVC films Winshield and German Imovel to ensure the best colors and natural texture of products. There are three warehouse items available: anthracite, golden oak, walnut.

Aluminum alloy production

High-tech equipment makes it possible to create high-quality aluminum alloys, as well as produce alloys 6063 and 6060, which meets the highest requirements according to EN 573-3.

Production of aluminum profiles

Our company has 2 modern presses with a production capacity of 650 tons per month. The profile is produced by extrusion using high-precision tools. The matrices are prepared by nitriding. Artificial aging of the profile, in order to ensure its physical and mechanical properties, is carried out in aging ovens. We have German-made thermal bridges for warm aluminum profiles and anodized aluminum profiles. It is possible to supply special extrusion directly from the factory in the color and required size.

Powder coating

The paint shop paints aluminum profiles using the polymer coating method with preliminary chemical preparation. The use of powder paint produced in Turkey, Italy, Greece allows us to obtain a glossy and matte surface structure in a range of colors on the RAL scale. The coating is resistant to external influences and retains its original appearance for a long time.

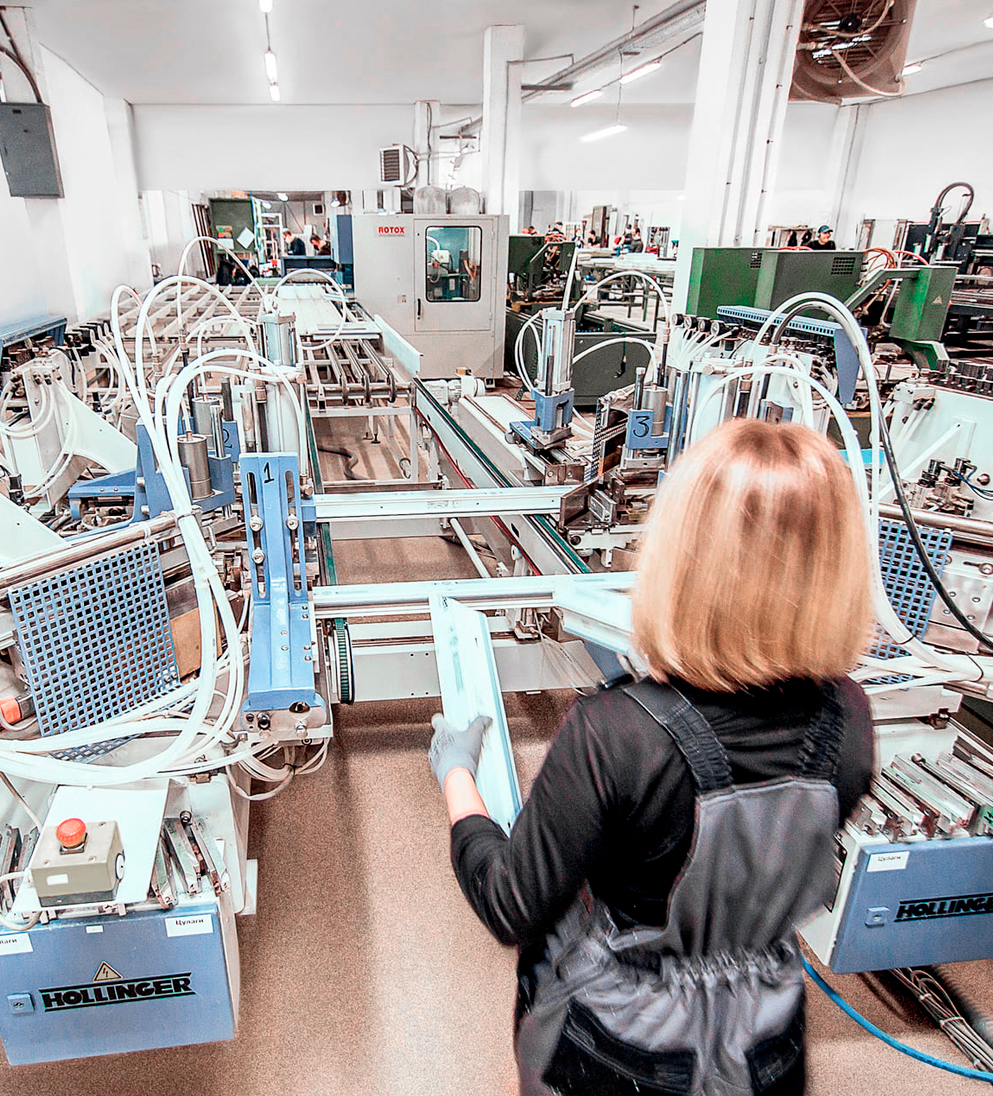

Production of translucent consrtuctions

The production manufactures structures from aluminum and PVC profiles. Due to the use of high-precision equipment manufactured by Lisec (Austria), Elumatec (Germany), STB Fimtec (Italy), Pressta Eisele (Germany), high quality products are manufactured that fully meet the requirements of users. Production area up to 5000 m².

Insulating glass production

The workshop for the production of double-glazed windows is equipped with automatic lines from the Austrian company Lisec. All processes are automated - from glass cutting to the process of secondary sealing and filling of double-glazed windows with inert gases. We use high quality materials from the largest European manufacturers such as Fenzi, Alupro, Profilglass, Grace Davison. Double-glazed windows can be of various shapes and sizes. Production capacity is more than 60 thousand double-glazed windows of varying complexity per month.

Metalworking shop

The company includes a mechanical workshop that produces a large number of components and fasteners for windows, doors and facades. The machine shop has sections for cutting, welding, seaming, plasma cutting, turning and milling machines, stamping, etc. There is also sandblasting of products, which allows for high-quality painting due to better adhesion of paint and profile.

Production of decorative ceramics

To produce our products we use high-quality environmentally friendly materials. Our products are made entirely by hand, so no detail is too small for us. We take the process of creating every detail responsibly. We draw inspiration from nature, its lines and color harmony, while at the same time we do not separate ourselves from the modern world and fashion trends.

Production of PVC panels

PVC panels and profiles TM Decomax are produced on modern, high-tech equipment of leading European companies using high-quality and environmentally friendly materials that do not emit harmful fumes and, accordingly, are not harmful either during production or during operation. In addition to standard white panels, we can offer panels decorated using lamination, flexo printing or thermal transfer. More than 50% of the Ukrainian PVC panel market is our product. Our clients are large retail chains.

Production of decorative wall panels

Framex panels are manufactured using advanced technologies, combining small thickness and large dimensions with resistance to mechanical stress, chemicals, wear, and scratches.

Warehouse space and logistics

Constant availability in warehouse of more than 400 tons of aluminum and 2000 tons of PVC profiles ensures uninterrupted execution of customer orders. And bar coding of products minimizes the possibility of errors during shipment. During basic packaging of goods, all structures are secured to a pallet or wooden slipway and wrapped with stretch film, fixing if necessary cardboard, corrugated cardboard or foam. The result is a reliable protected structure that can be unloaded using a forklift. Our own logistics department allows you to select a transport company that will deliver products within 5-10 days not only throughout Ukraine, but also to any country in Europe.